Table of Contents

Rakia drink (Rakya) is a fruit or grape-based spirit embodied in the everyday life of many Balkan countries. From birth to death, rakia is continuously present throughout significant life moments. It is not unusual to incorporate the beverage in different rituals or events: birthdays, prom nights, weddings, name days, problem-solving days, turning enemies into friends, and a drink connecting people for centuries.

There is also a belief that rakia has healing powers (cures diseases, beats any virus, soothes pain, brings down a fever), and having one a day will keep you healthy, which is excellent. Still, this habit also causes a slight problem; people can’t just stop with one drink; usually, they have more than one, which defeats the purpose of rakia’s “healing” powers.

For the locals, rakia is not just another drink but a lifestyle. Even if they don’t drink, people usually have rakia at home. Offering rakia and showing your guests they are welcome is a common courtesy in case of unexpected guests.

A long time ago, my grandfather told me a story about how people didn’t have much in the past, but they were happy and overcame their daily problems with a smile. Still, at the moment, they didn’t have any rakia, salad, or meze at home to offer to their guests; that was the time they felt poor and unhappy.

“Rakia Power” is embedded within the cultural lifestyle of the regional countries. It is above politics, alien technology, and even the “Force.”

Does that mean everyone in the Balkans is drinking? The rakia, or its meaning to people’s lives, is much more than the EU bureaucratic spirit drinks classification of it as a simple wine/fruit spirit/distillate.

If rakia is called “wine spirit/fruit spirit,” what is brandy made of? Maybe we can start referring to vodka as beer distillate.

After all, most of the liquors before distillation more or less begin as wine or beer, and I understand the word rakia encompasses a broad spectrum of grape/fruit brandies. Still, it could’ve been used as a separate family name, under which all wine, fruit, and marc spirits can fall within that category and be classified by flavour.

On a local level, almost every country in the region brags about rakia’s ownership and claims it as their national drink. This is fine for national pride or sitting at the table and arguing who makes better rakia. Still, if rakia is to be regarded as a style of drink, like vodka or whisky, the ownership should not be confined to a particular country.

Based on archeological evidence, I know the Bulgarians have the right to claim the rakia, which was made for the first time in Bulgaria. Still, instead of arguing about who created it first, the regional countries should discuss their case for rakia not being confined to a particular geographic place but more of a style of drink.

Think of whisky(ey) history; the Irish claim they invented whiskey in 1405, and the Scots claim that. Still, it didn’t stop whisky from becoming a type of drink made by many countries and defined by their local geographic location (Canadian, American, Japanese, Taiwanese, etc.)

The same can be accomplished with rakia. We can have Albanian, Bulgarian, Serbian, Romanian, etc., under the official umbrella of rakia, not the lovely name of fruit/marc spirit. That will also contribute to more extensive use in cocktail recipes and create an opportunity to increase the rakia overseas marketability and showcase its versatility, not just as a straight drink but as a spirit capable of carrying complex flavour into delicious cocktails. That also aligns with the 1806 cocktail definition of being a “..stimulating drink…”

If the producers are looking to expand their overseas markets, their main focus should be on breaking the stigma of rakia as being firewater and drunk only as a shot. Cooperating in marketing and education will eventually lead to reaching new markets; an easy way to begin with will be by creating rakia cocktail recipes as part of a marketing strategy, equally suitable as aperitif or digestif, organizing cocktail competitions, and changing the world perception of rakia.

Rakia Drink Types

There are many rakia flavours; some are served before dinner and some after, but in terms of the primary source of production, there are two main varieties:

Grape-based

- It is usually made using a fragrant variety of white and ripped grapes, such as Muscat, Sauvignon Blanc, or Dimyat. If the rakia is produced from the remainder of the wine fermentation (marc), in Bulgarian, the raw material is called “jibri” and is distilled to reach 65% alcohol content. The sweetness of the grape will determine the amount of sugar needed; the best results are usually achieved with a sugar content of around 24%; if it is lower, you can add extra sugar.

Fruity and floral scents are the dominant aromas, but the flavour will depend not only on the type of grape but also on when it was picked up.

Fruits-based

According to the raw material, three main types of rakia can be distinguished:

- Spirits are obtained with pome fruits, of which apples and pears are the most common.

- Those obtained with stone fruits, mainly sweet cherries, sour cherries, plums, apricots, and peaches.

- Distillates obtained from berries.

Any fruit with enough sugar to produce ethanol can be used as a base product.

Here are some of the most common fruits and rakia types in Bulgaria and the region:

- Apricots, apples, figs, quinces, plums, peaches, pears, apricots, berries, sour cherries, walnuts, bananas.

- Šljivovica (plums)Bilkova – infused with herbs

- Krushova (pear)

- Anasonliyka (with anise)

- Muskatova (Muskat grape or any preferred grape variety)

- Dzhibrova / grozdanka (grape pomace /grappa)

- Kaysieva (apricot)

- Praskovena (peach)

- Krushova (pear)

- Yabalkova (apple)

- Chernicheva (mulberry)

- (Quince), smokinova ( g)

- Chereshova (cherry)

- Vishnovka (with sour cherries)

- Plodova (mixed fruits)

- Gyulova (with roses)

- Klekovača (with juniper)

- Orehova (with walnuts)

- Medena (with honey)

Once the producer decides on the type of rakia, it is time for the fun to begin. A few steps need to be undertaken to get the final product.

- raw material

- fermentation

- distillation

- stabilization, if needed

- filtration

- aging in wooden barrels

- blending, it is the distillers’ decision

- Spirit bottling

Plum spirit (Slivovitz) process flow diagram

Raw Material

For major producers to obtain a suitable grape/fruit variety, its readiness, organizing the transportation, storage, and preparing the distillation facility are necessary steps to set up a proper production.

The choice of the base material is vital in terms of the chemical composition and concentration of different compounds (congeners) found in the distilled spirit. Even if they make up a tiny percentage of the total, they are significant contributors to the flavour of the rakia.

Grapes

The majority of Northern Hemisphere harvesting occurs in late August to early October. The right timing is a crucial step in winemaking and rakia, and a few factors determine it.

- The grape’s ripeness is measured by sugar, acid, and tannin levels.

- The weather conditions – how they affect the grapes if there is a forecast of hail, rain, and frost, which might have a negative impact by causing vine diseases.

- A choice of using mechanical harvesting or hand pickers.

If one is to make grappa/marc rakia or brandy, a decision must be made regarding the type of grapes needed. For instance, we need a rich grape variety for marc rakia, showing its aroma in the final distillate. For brandy/cognac, we will probably go with not-so-aromatic grapes since the main flavour will result from longer maturation, which is critical to achieving the desired smoothness and character.1

In the case of rakia, the idea is to preserve and showcase the underlying aroma of the based product. The achieved perception of quality will rely heavily on the smell and taste of the fruit itself and how the underlying flavour is recreated during the distillation.

Fruits

When working with fruit, we usually talk about fermentation and distillation of mash, not liquid, making the fermentation process very complicated, especially the distillation process. The choice of distillation is still crucial to avoid burning and keep the chemical compounds responsible for flavour.

At the same time, some fruit brandies “like” aging, while others find it difficult or not to tolerate aging in wooden casks since they rely heavily on the aroma and taste of the fruit itself being presented in the distilled spirit.

Rotten and mouldy fruits should not be used because they produce low-quality and defective brandies. Rotten fruits, especially plums and apples, produce brandies with a high methyl alcohol content, which is poisonous.

The harvested fruit must be processed immediately. Any delay degrades the quality and reduces the yield. If working with stone fruits (apricots, peaches), the stones must be removed as they contain a lot of amygdalin, which is highly poisonous and unpleasant. If working with seeds fruit, they need to be ground before fermentation.

According to Blagoy Popov, a long-time coppersmith and still maker.

The secret to each good-quality rakia is in the selection of the appropriate fruit. It must be well-ripen and pitted. The distilling process is very important because you should preserve the fragrance of the essential oils, which make rakia taste good.

Blagoy Popov, Radio Bulgaria2

Fermentation

Fermentation primarily aims to turn grapes/fruits into a grape juice/mash and utilize the yeasts to transform sugars in the juice into an alcoholic beverage (ethanol and carbon dioxide as a by-product).

Before the base material goes into the fermentation vessels, it must be washed to remove any contaminants or chemicals used during the growing process. Grape fermentation is often done in stainless steel tanks, concrete vats, or various wooden vessels on a smaller scale.

The resulting fruit pulp is transferred to wooden barrels or plastic cans for fermentation filled half to 2/3 of the capacity, and an activated yeast can be added to speed up the process. The reason is that the washing process also removes spores and yeast from them, making it hard to initiate spontaneous fermentation. The added amount is usually in the range of 2-4% of the mash volume.

If using ambient yeast (wild yeast-native yeast), the fermentation might take longer, but it tends to lead to “terroir-specific” flavours in winemaking.

An essential element here is to measure the sugar content of the mash, which should be between 20% and 24%. Many people add sugar to kick-start the fermentation or increase the sugar content. I prefer rakia without any added sugar during the fermentation, but if the sugar content is higher than 25%, add water to the mash.

After the desired sugar content in the juice has been reached, stir the grape a few times a day to release the juice. We do that for 4-5 days until the sugar content reaches 03.

How do we know when the fermentation is done and when it is time to move to the next step – distillation? The simple answer is when all the sugar has been converted, but other ways are to check if the mash is fermented and ready.

Stirring the fermented material does not release gas bubbles and no foam forms on the surface.

if a lighted matchstick served over the mash goes out, the process is not over. If it continues to burn, then the fermentation is over.

By tasting – if you feel sweetness, although weak, the fermentation is not over yet. If bitterness is felt, the process is over and the mixture can be boiled.

https://rozbul.com/

Before distillation, the grapes are passed through a pressing machine to separate the grape juice for distillation. The remaining material is separate and washed and can be used for the grappa (marc/djibri) style of rakia.

The third option is to make rakia by mixing the remains of the grape material (marc) and juice.

Rakia Distillation

In Part One, we saw how the distillation process evolved over the millenniums without mainly focusing on the details of the actual process at present times. This post will look at the types of distillation most commonly used for making rakia.

Distillation is the process in which a liquid is vaporized (turned to steam), recondensed (turned back into a liquid), and collected in a container.4

The distillation process is an ancient technology for separating liquid mixtures into their components by applying heat and taking advantage of the differences in their boiling points. It is performed to concentrate ethanol and desirable aroma compounds, as the goal is to obtain the best balance between the congeners present.

The last objective is even more important for the fruit spirits; We must recognize the raw material from which the spirit was obtained.

The chemical composition of the mash or juice consists of many compounds. Still, the primary ones are ethanol, water, and many other congeners with a very large boiling point difference (e.g., acetaldehyde 20.8°C and benzaldehyde 179°C), which are responsible for the authenticity and flavour of the spirit.

Not all the congeners have pleasant aromas, and some need to be removed during the distillation process not to affect the final product’s intended quality.

Using different distillation equipment is an important decision that needs to be made, as each type may still influence the spirit’s final flavour profile.

Two types of stills are used in distilling wine/fruit spirits: Charentais alembic pot still and batch distillation columns.

Batch distillation is usually a two-stage, mainly if one still uses alembic.

- The first stage entails taking wine and distilling it until the alcohol strength is 28-30% alcohol per volume.

This is known as low wine. Low wine can be stored for an extended period, as it is protected against microbial spoilage. - The second stage is distilling the low wine and collecting it in three fractions.

Batch distillation can also be one-run if single-column batch distillation equipment is used.

Low and High Wines

The distillate at two different stages. Low wine is after it has completed its first distillation. High wine is after its second. From that point, different types of alcohol are created, based on the number of distillations.

It is the same process, whether distilling for small personal needs or in a large industrial environment.

For instance, the tradition of making rakia in the local community is still alive. Whether one makes it at home or goes to a local distiller, Kazan (казан) in Bulgaria, the whole process is a full-day experience. We picked/bought the grapes, fermented them, brought them to the place, had a few drinks, and had barbeque with other people while waiting for the elixir to come out.

The stills used vary from homemade, old traditional ones to modern pot stills batch column distillation equipment. Before venturing into a distillation, though, without much experience, It is imperative to know that improper distillation might lead to severe health issues. The best way is to go to a licensed facility and let them do it.

Once the distillation starts, it boils down to a simple principle on how and when to do the cuts, categorized into three principal fractions: heads, hearts, and tails.

The heads contain a higher concentration of low boiling point components and mainly contain undesirable compounds. They are responsible for an unpleasant, strong, and sharp flavour; there is also a higher concentration of some toxic compounds, which need to be discarded and not be part of a distillate.

The hearts are the best part of the run, right after the distillation’s head fraction. This distillate is rich in ethanol and has fruity aroma compounds. The heart cut differentiates with a clean taste, lacking the sharp bite of the heads.

The tail fraction is the last cut to be eliminated right after the heart. It contains unpleasant fatty and oil compounds carried out by water and usually can be identified by the distinctive unpleasant smell of “wet dog.” The tail fractions (with or without head adding) are collected and redistilled because they contain a relatively high alcohol concentration and valuable congeners.

Simply put, we are after the hearts part, where the separation will be left to the master distiller or the local rakia distiller. It doesn’t matter if it is during the first or third run. The cuts must be made appropriately, thus eliminating potentially harmful substances from the final product.

Knowing when to do fractional alcohol distillation is essential for the health of the intended spirit and its flavour profile.

That will also determine the amount and the types of congeners left in the rakia, contributing to a well-balanced drink, or on the other hand, might lead to a non-desirable flavour, overpowering and masking any other aromas.

Undoubtedly, having great equipment and knowledge helps, but distillation is still a form of art.

Let’s go back in time for a moment, in 1512 to be precise, and look at one of the first books on distillation, Liber de Arte Distillandi de Compositis (distillation apparatus for aqua vitae, i.e., spirits of wine) by Hieronymus Brunschwig. He wrote a comprehensive book on distillation, widely accepted as one of the earliest writings devoted exclusively to chemical technology. His work was based on earlier records on the distillation of herbal remedies and included a wide range of alchemical distillation techniques.

It was a continuation of what the alchemists were trying to accomplish through distillation, a goal to archive powerful, pure chemicals such as alcohol and strong acids by sequences of steps of “separation” and “recombination.”5

Granted, nothing much has changed since then; we do have much more sophisticated equipment, but still, like the old alchemists, the distillers need to taste the final spirit and decide where to separate the fractions and the number of congeners present.

A few ways can help determine the point of separating the essence of the base material from the unwanted chemical compounds.

First step – the Art of Tasting

The cuts in the head and tail parts can be made based on the distiller’s sensory evaluation. The presence and absence of volatile congeners that give the head fraction a sharp, strong, and unpleasant smell can be used as a cut point for switching to the heart fraction. Also, the tail fraction starts with flavour that gives the distillates a faded, dull character, and it should not be difficult for an experienced distiller to do this by smell.

Taste and smell remain the most reliable method of determining when to cut.

Second Step

The second indicator of cut points is the percent alcohol of the spirits flowing out of the still, especially for separating the heart from the tail cut. The ethanol strength could be the limiting value for switching from the heart to the tail. This limiting value varies depending on the distillation equipment involved, the fruit variety used, the quality of fermented mash, etc.

Third Step

The third indicator of the cut points is the temperature of the vapour before it enters the condenser. The distiller can make the first cut in the run when the vapour temperature in the copper pipe reaches approximately 74–76°C. The heart cut from the tail can be produced when the vapour temperature in the copper pipe reaches around 87–88°C, and the tail distills until the temperature reaches 92–93°C when distillation is over.

Main Distillation Techniques

Two main distillation techniques are used in making spirits: Batch and Continuous. They use different equipment, and choosing one depends on the base material and the desired final product.

Two different stills are predominantly used for rakia (fruit or grape-based) production: an alembic copper pot still and a batch distillation column. One important note is that the distillation must be carried out slowly, or it may lead to hot spots and degradation of the final spirit.

Alembic Pot Still Stages

The first run (raw spirits) has alcohol content around 15–25% v/v, depending on how rich was on alcohol was the fermented mash.The second run aim is to purify and increase the strength of the alcohol and it has to be carried out much more carefully than the first one. In the second distillation is where the fraction separation is applied.

- The head fraction (or cut) is collected at 1% to 2% per 100 L raw spirits. The amount of head cut depends on how damaged the fermented mash is. If the fermented mash waits long until distillation, the higher head must be separated and thrown out, as it carries many toxic compounds.

- The heart fraction starts coming out at 60 to 70% (v/v) of ethanol (depending on how rich in alcohol raw spirits were) and collects until the alcohol decreases to 40–50% (v/v). The exception is Williams’s pear spirit. In the production of this spirit, the heart fraction needs to be cut at the lower alcohol degree (below 40%, v/v) due to the ethyl diaconate ester, which distills at the beginning of the tail fraction. This ester is very important for the Williams pear spirits aroma. This is not the only spirit where the cut may vary based on lower alcohol degree, as with some plum varieties.

- After the heart is separated, the tail fraction distills until the end, when the alcohol degree is achieved, 3 or 5% (v/v). The tail is collected and could be redistilled later or saved and added to the next run.

The obtained heart fraction usually has an alcohol strength of 45–70% (v/v), depending on the kind and variety of fruit used for spirits production.

If the undiluted rakia has a higher proof than the recommended one (40° —45°), it must be diluted using distilled water.

For example, to reduce the alcohol content of 1L of brandy from 56 ° to 40 °, we must calculate how much water must be added.

We can use the formula B= (A1 – A2)/A2 x P or the calculator below.

| P | undiluted spirit |

| A1 | the strength of the undiluted spirit |

| A2 | proportion to the increase in the volume of P + B |

| B | the amount of water |

The dilution can be done in the following way6.

Depending on the quantity, the brandy is poured into a suitable sized container, allowing freely stirring. With constant stirring, the calculated amount of water is added in a thin stream to the rakia. When the amount of water is greater than 2-3 liters, it is recommended to add in portions, after each amount of water to the rakia stir vigorously for homogenization the mixture. Wait a few minutes between before adding another portion of water. This is done in order to prevent possible turbidity of the spirit, which would happen if the entire amount of water is poured at the same time.

Prof. D. Tzakov

The video linked below explains how fractional cuts are made during distillation. It is only for information, not advice on making rakia or any other spirit at home.

Most spirits are distilled twice, but some undergo only one distillation run (some fruit brandies, Armagnac), and the different fractions must be separated at that time. For instance, if we compare the Slivovitz distilled ones to one distilled twice, we can see the difference in the Slivovitz. The one produced by single-stage distillation has double higher acetic acid and esters, a higher content of higher alcohols and acetaldehyde, and a lower methanol content than Slivovitz produced by double distillation.

| Stage of distillation | Alcohol (% v/v) | Total acids (g/L) | Aldehyde (mg/L a.a.) | Esters (mg/L a.a.) | Higher alc. (mg/L a.a.) | Methanol (% v/v a.a.) |

|---|---|---|---|---|---|---|

| Single | 43.8 | 1.39 | 448.19 | 6611.4 | 4779.39 | 0.84 |

| Double | 60.6 | 0.36 | 209.68 | 3243.0 | 3264.11 | 1.03 |

Batch distillation

Batch column distillation requires just one distillation to achieve a high alcohol degree in single-stage distillation, during which these fractions are also separated (head, heart, and tail).7

It is similar to continuous distillation, but also there are some differences.

A batch distillation can be done in a single distillation column. There, multiple components can be separated into separate receiver tanks. When the distillation of one batch is completed, the column can be used for a completely different component mixture quickly and efficiently. Also, this process can be completely automated and is often employed when smaller quantities are distilled.

This process gives a very high purity of the separated chemical and maximum flexibility (a single batch process can handle several different substances).

Continuous distillation

The feedstock is added in the continuous distillation column, and the distillate is drawn off without interruption. Each fraction stream is taken simultaneously throughout the operation; therefore, a separate exit point is needed for each fraction. In practice, when there are multiple distillate fractions, the distillate exit points are located at different heights on a fractionating column.

There are no interruptions for this process until the completion of the distillation, and it has high efficiency for separation.

Differences between Batch and Continuous Distillation

| Batch Distillation | Continuous Distillation |

| Changing the distilled mixture takes a long time in the continuous distillation process. | The number of columns required is N-1, where N is the number of components to be separated. Therefore, a multi-component feed will need multiple columns with its reboiler, condenser, and multiple columns. |

| The efficiency of a batch distillation process is low compared to continuous distillation. | The number of columns required is N-1, where N is the number of components to be separated. Therefore, a multi-component feed will need multiple columns with its reboiler, condenser, amultiple columns. |

The size of the still pot dictates the batch size. | The quantity that can be processed is limited only by the amount of upstream feed storage. |

| In the continuous distillation process, it takes a long time. | Changing the distilled mixture takes a long time in the continuous distillation process. |

| The number of columns required is N-1, where N is the number of components to be separated. Therefore, a multi-component feed with its reboiler, condenser, and reflux system will need multiple columns. |

https://rccostello.com/wordpress/distillation/batch-vs-continuous-distillation/

*Tips on How to Clean pot still.8

The ideas are based on the local distillers’ (казанджий) experience on how to clean a small pot still.

- To remove stains from the walls of the pot:

- Masted boiled potatoes are left on the contaminated areas until dry and then cleaned with a soft brush or woollen cloth.

- Clean with onion rings.

- If the problem with greening the pot still

- use a weak solution of ammonia.

- To remove rust

- It can be fixed by rubbing with a brush soaked in a mixture of 1 part by weight of sulphur and two parts by weight of nitric acid, after which it is quickly rinsed with clean water.

- To remove soot:

- Use gasoline or gas, soap, lye or turpentine oil.

- Before each brewing, clean the pot with vinegar and salt to remove deposits.

Distribution of volatile compounds during distillation by using different distillation equipment

Both distillation techniques use the same principles of different points of alcohol evaporation. We have the same finishing parts (heads, hearts, and tails). Still, regardless of that, several essential differences in the content of ethanol and congeners are crucial for the flavour of spirits and, therefore, critical to the choice of distillation equipment.

Generally, when we want to preserve the flavour of the distillate base, the better choice will be the pot still, by using its advantage over the continuous column still of being not as efficient and allowing some of the desired congeners/flavours to stay in the spirit.

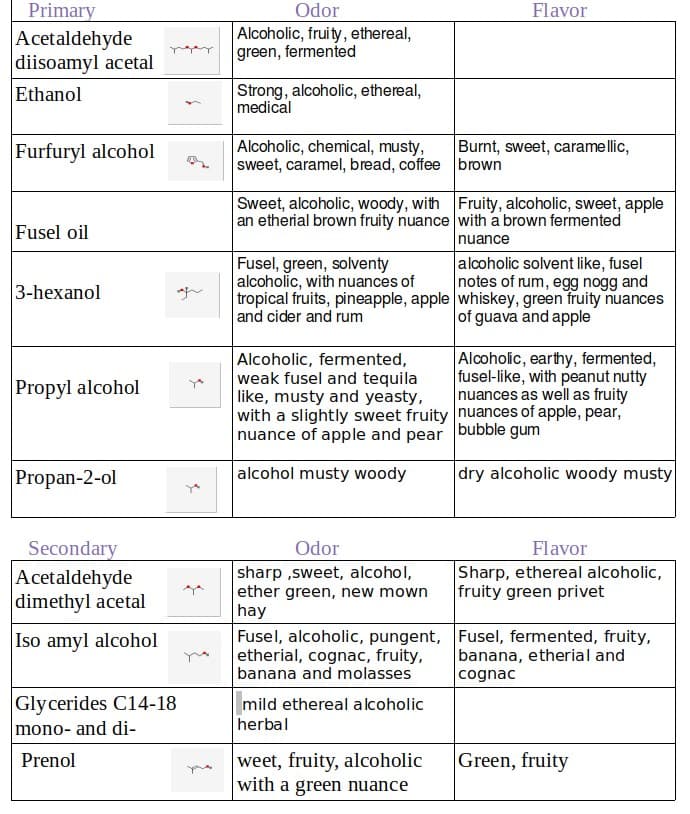

Other factors affect the perceived quality of distillates as defined by the aroma compounds, which can be classified into four groups:#aroma.

- Primary aromatic compounds, whose entire aroma appears precisely as in the fruit during ripening;

- Secondary aromatic components, formed during alcoholic fermentation;

- Tertiary aromatic compounds formed during the distillation process;

- Quaternary aromatic compounds are formed during maturation (Tesevic et al., 2005).

Some of the alcohols are present in distillates and are used to reference their influence over the perceived aromas.9

Distilling strains of S. cerevisiae produce congener classes; depending on our skill, the final flavour profile will be different.

The distribution of the congeners depends on what is still being used.

The entire line is alembic distillation; the dashed line is column distillation, and –*– shows the cut where the higher component is accumulated.

The main reason for those differences is that those compounds show different behaviours depending on alcohol content in liquid and vapour during distillation. They will distill following their relationship with alcohol rather than their boiling point.

Methanol

Methanol’s boiling point is 64.7°C, and it is completely soluble in water. It appears in almost equal concentration in all distillation fractions, and separating the methanol from the ethanol-water mixture is challenging.

Methanol presence in fruit-based rakia is significantly higher than in grain distillates. Pectin, a natural component of fruits, can prove that the distillate was based on natural fruits. The methanol concentration depends on the fruit treatment, the amount of pectin present, distillation, and the fruit’s kind and variety.

According to Dr. Eng. Nikolai Bakalov10,

Methyl alcohol is obtained due to the enzymatic degradation of pectin substances during the fermentation of fruits (apples, pears, quinces, prunes, etc.). The fermentation temperature stimulates the formation of methyl alcohol and it can increase from 2 to 6 times. Fermentation of fruit pulp is best carried out at a temperature of 15 to 18 degrees, and if not controlled, it can reach 35 degrees and then accumulate maximum amounts of methanol. The duration of storage of the mash before distillation is also very important, because with prolonged storage even over 6 months, methyl alcohol can increase by 2 to 3 times, so the distillation is best done immediately after fermentation. Therefore, we must not allow too much methyl alcohol to form during fermentation and storage of the mash before distillation.

When a low-alcohol mixture (like fruit-fermented mash) is still distilled in a simple pot, methanol will go out following its solubility in water rather than its boiling point. Being highly soluble in water, it will distill more at the end of distillations when vapours are more prosperous in water.

That means methanol will accumulate more in the tail fraction during distillation in an alembic pot.

When distillation is done using a column still using a high-alcohol mixture, methanol evaporates following its boiling point. It is present in a higher concentration’s first fraction of the distillation. When a distillation column is used, it appears mainly in the head fractions.

Higher Alcohols

Many people, especially those using local/community distillers, are primarily concerned with the level of methanol in the final product. Still, the higher alcohols can have the same or more significant negative impact on the quality and safety of the rakia.

Among the hundreds of compounds in alcoholic beverages, the higher alcohols and esters are the most important. They are formed during the fermentation process and are considered a by-product of alcohol fermentation produced by yeast during alcoholic fermentation. Their quantities in the distillates are managed during the process of fractional distillation.

Since the higher alcohols have boiling points lower than 200°C and are alcohol-soluble and partially water-soluble during distillation of a low-alcohol mixture, they want to escape the water/mash. Although they have a high boiling point, they will appear mainly in the head fraction.

When using a column still, a distilling mixture with a higher alcohol concentration (higher than 40% (v/v)) distills following the boiling points; their concentration will increase as the distillation process progresses, which explains why the higher alcohols are present in the tail fraction of distillation as opposed to the head fraction in a pot still process.

The higher alcohols^ are responsible for the pleasant flavour and the character of fruit distillates only when they are present in smaller quantities. On the other hand, high amounts can affect the distillate flavour by producing a strong, pungent smell and taste and being mildly toxic.

They are also the most significant volatile aroma compounds in distilled alcoholic drinks.

According to research between 2009-2013 conducted in Skopje, North Macedonia11 were the most critical higher alcohols of grape and plum brandies.

- i-propanol,

- n-propanol,

- i-butanol,

- n-butanol,

- i-amyl alcohol

- namyl alcohol.

For example, i-amyl alcohol, a contributor to the fruity aroma, is the most abundant alcohol in grape and plum spirits.

Esters

Esters are essential compounds due to their particular contribution to flavour and aroma and are usually associated with a pleasant, fruity, and flowery fragrance.

One of the most common esters in wine is ethyl acetate, a product of the volatile acetic acid and the ethyl alcohol generated during the fermentation. Its presence in the final product will vary widely, from lower grape rakia to much higher plum rakia.

The boiling point is 77.1°C, which explains why ethyl acetate can be found in the head fraction of both distillation processes, and it has the largest presence in fruit spirits as of more than 80% of all the esters.12

The importance of ethyl acetate is that the ratio of total esters and ethyl acetate indicates the quality of spirits.

On the other hand, the high ethyl acetate level can indicate prolonged raw material storage and potential acetic bacteria spoilage. 13

According to Galya Mihailova, head of the testing laboratory at the National Institute for Research of Wine and Spirits (NIIVSN) in Bulgaria,

A high level of esters, such as ethyl acetate is more harmful than methanol, and it is formed during the fermentation process if the producers are using spoiled and molded material (fruits, jams, etc.).

Particularly dangerous is the hydrocyanic acid, which is the most common in fruit brandies- plums, apricots, peaches, who are distilled with the stones.

https://www.24chasa.bg/novini/article/4393478

Other chemical compounds found in distillates

- Acetaldehyde is a fermentation by-product associated with the type of yeast, fermentation, and distillation. Present in the head fraction. It is associated with intoxication and ‘hangover’ symptoms such as nausea, vomiting, restlessness, sweating, confusion, decrease in blood pressure, higher heart rate, and headache.

- Benzaldehyde is present in spirits in much higher concentrations if the mash is fermented with stones. A smaller presence is desirable, as it introduces bitter almonds, marzipan, and cherry aromas.

- Furfural is an aldehyde formed during distillation. It is a part of fruit distillates and acts as proof of natural products used as a base.

- Acetic acid accounts for more than 90% (v/v) of the total acidity in spirits. Acetic acid is a by-product of alcohol fermentation. Lower presence means better quality from a consumer perception point of view; higher levels introduce a sour taste and pungent smell.

Many more high alcohols and volatile acids are found in the final products. Some are desirable, and some are not, and a few factors influence their level of presence.

- Fruit variety fermentation conditions – probably the most crucial part is the choice of products and their handling.

- Distillation—when the fractional distillation/cut is done—is a form of art that involves finding the balance of the congeners contributing to the final flavour.

- Distillation equipment—Using pot stills instead of column stills will allow the preservation and achievement of the more pronounced character of the material used (grapes/fruits). Due to its efficiency, the pot will still result in cleaner spirits. The choice of equipment will depend on the distiller’s intentions, cost estimate, and flavour strength of the materials.

Based on the last two reasons, one might choose batch column distillation as it is more efficient, cost-effective, and suitable for less fragrant fruit/grapes due to the ability to achieve higher extraction of esters and then the alembic still.

As I mentioned, the aroma compounds in fruit distillates result from complex interaction and contribute to the final flavour profile formed during three or four production stages, depending on the product maturation period, if any.

- During the ripening of fruits

- During fermentation

- During distillation

- During maturation

Stabilization

Stabilization in the food and beverage world is improving the viscosity, texture, longevity, and appearance of food products or drinks.

In the wine industry, cold stabilization prevents tartaric acid crystals from forming after bottling. If wines are not cold stabilized, crystals may form when consumers store bottles of wine in the refrigerator for long periods. Later, when you serve the wine to friends or customers, they might see tiny crystals on the bottom of the glass, which looks like broken glass.

In the food industry, producers use stabilizers or hydrocolloids in their recipes to stabilize and improve a product’s taste; chefs and bartenders create and change the appearance or texture of dishes and drinks, collectively known as Modernist Cuisine or Molecular Mixology.

If we look at a few of these additives, we will probably recognize them.

- Xanthan gum – is used in ice cream to prevent the formation of ice crystals and improve smoothness.

- Carrageenan is used in ice cream and plant-based milk, such as soy milk, to improve mouthfeel and increase viscosity.

- Arabic gum – beverages

There are many more hydrocolloid compounds with similar functions and widespread use, but the question is, do they belong in rakia making, and why might someone decide to use them?

Filtration/Clarification

Organic and non-organic origins might cause cloudiness in fruit brandies.

- Organic origin.

- The turbidity of organic origin is mainly due to increased amounts of tannin, ethanolignin, dextran, and other organic compounds. Rakia is clarified with gelatin, egg white, or bentonite in such cases. Egg white is preferred at home because it does not cause over-clarification; the same applies to gelatin.

- Non-organic origin.

- Increased content of iron, copper (copper), and calcium. The latter occurs when using hard water for alcohol degree correction. Turbidity may also appear in cases where a large amount of water was introduced once. To prevent this turbidity, it is recommended to use distilled water and import it in small portions, in the form of a thin stream with constant stirring of the brandy.

- White clouding of brandy.

- Although rare, sometimes brandy comes out of the pot with slight whitish turbidity. This phenomenon may be due to the material to be boiled or the distillation regime. In such cases, it does not require processing (clarification). The brandy clears spontaneously when aged in a wooden or glass container with added wood.

- Sometimes, suppose the colour has a blueish, greenish, or brownish hue. In that case, the reason might be the interaction with the material of the fermentation vats (copper or iron), which means the rakia has absorbed some of these elements. The best containers for fermentation are wooden and plastic.

To clarify, making rakia at home is not easy, and according to Prof. Tzakov, it is impossible, but here is one recipe from his book “DIY Quality Homemade Rakia—the Secret of Prof. D. Tzakov.”

Clarification with Egg White

The dose for 100 liters of brandy is one egg white.

The egg white is whipped into 100 ml lukewarm water (35-38 ° C) to obtain an emulsion. This can also be done with a mixer.

A little brandy (about 1 liter) is added to the whipped protein, stirring constantly.

The prepared emulsion is introduced into the brandy in a thin stream intensively stirring. Leave alone for 5-7 days. During this time, the precipitate formed falls on the bottom. The clear brandy is decanted (separated) with a hose attached to a wooden lath so that its end is 4-5 cm higher than the end of the lath. This is done so that sludge overflow can be avoided during suction and turbid again brandy.

If the clarity is not sufficient, the brandy can be filtered (strained) through two or three layers of gauze or cheesecloth. The precipitate is also filtered through two or three layers of cheesecloth. The resulting clear brandy is added to the other and poured into glass bottles. Plastic screw caps can also be used.

Flavor Improving

The reasons to use any of the following options in rakia making might be a taste you don’t like, something that went wrong during the fermentation, improper distillation cuts, or no patience to wait for spirit maturation.

Father modification to the colour, taste, and aromas is possible after the distillation process has been completed, and it is a choice based on the producer’s satisfaction with the distillate.

- Sweetening is used to stabilize and improve taste.

- Rakia does not tolerate sweetening, but a slight, barely perceptible sweetening softens the taste and becomes softer. Sweetening is usually done with a pre-prepared syrup of water and sugar. The syrup can be prepared coldly or warmly; simple syrup is made cold or heated.

- Using honey instead of simple syrup, similar to simple syrup, will add taste to the spirit.

- How to—Add the syrup to the rakia with constant stirring; depending on the amount of brandy, the syrup can be between 100 and 200 ml. After each serving, the brandy is stirred vigorously and left for ten minutes to homogenize. Take a sample and taste it. If the taste is unsatisfactory, add the second portion of sugar syrup. Stir, wait 10 minutes, and retake a new sample.

- It must be left for a week to balance, then poured into bottles and stored in the basement.

- Glycerin – colourless, odourless, sweet-tasting. And they are usually added to vodka. The usual added amount is between 0.5ml and 2ml per 1L.

- Gum Arabic improves the mouthfeel of the spirit. It is added in an amount of 0.5 ml to 50 ml per 1L.

- Due to the lack of barrels, toasted oak chips are usually used in glass jar maturation. The jar should be filled only 70% to give proper oxygen access to the distillate.

- Colouring

- Brandy is coloured after sweetening. If this is ignored, changes in clarity and colour may occur. Colouring is best done with natural dyes that are easily applied at home and, more importantly, are not harmful to health compared to chemical (synthetic) colourants.

- Aromatization of rakia can be done in different ways:

- By using aromatic fruits as starting material.

- Direct use of natural aroma sources during the fermentation or distillation is also possible.

- After distillation, indirect use of natural aroma sources—flowers, leaves, seeds, whole plants, and herbs—was done, similar to simple syrup.

- Figs – Use a few of them (5-7; more will change the spirit’s aroma) per 700ml, and keep it for 3-4 days.

In the case of spirits, the producers decide whether to implement such processes. If they opt for such a step, their goal will be to improve the smoothness of the alcohol and remove its harsh taste.

Maturation

Maturation is my preferred method of improving rakia’s flavour, letting the aging process work its magic and avoiding additives, but that’s my preference. As long as you enjoy your drink, go for it!

- Maturation – after distillation, the barrel of choice will determine and add aroma to the rakia. How long to keep it in the cask will depend on different factors, and no one answer fits all. Some of the factors to consider are:

- Type of cask – oak or cherry

- Size of barrels – smaller and new casks will speed up the maturation process.

- Ambient temperature of the storage place—in theory, a higher temperature above 20°С will speed up the aging compared to 10°С, but that will also increase the evaporation and affect the strength of the distillate.

- If you are unsure, keep it for at least a year. The interaction between the casks and the distillate will cause a change of taste—mellower and smoother—and a slight shift in aroma.

There are some brands or even homemade ones older than ten years; however, most of them are transferred into glass vessels after the desired barrel-aging time.

- The maturation of fruit brandies is usually shorter than that of grape ones, as the wooden cask negatively impacts the initial fruit flavour.

- Maturation in Glass Vessels.

- When the amount of rakia is small, and there are no suitable wooden containers, aging can also occur in glass (damajani). However, due to the lack of oxygen, the spirit is not enriched with phenolic compounds and, as a result, is not aging. It remains as it was poured, regardless of the duration of storage (aging).

To age, it is necessary to create conditions close to those provided by wooden vessels. This is achieved by adding wood to the brandy to extract phenolic compounds. Small chips, shavings, or sawdust from old dry oak wood are used in industrial and domestic production.

- When the amount of rakia is small, and there are no suitable wooden containers, aging can also occur in glass (damajani). However, due to the lack of oxygen, the spirit is not enriched with phenolic compounds and, as a result, is not aging. It remains as it was poured, regardless of the duration of storage (aging).

Blending

The goal of blending spirits is similar to making cocktails. We create nuanced and complex new drinks by mixing ingredients (spirits) with different maturation and flavours. Distillation is a form of art, and making blended spirits requires skillful master blenders who are aware of all the aroma properties and can balance them to create an enjoyable result.

Blending is not as widely used in the production of rakia as it is in scotch or brandy, and the reason for that is the choice of base materials and the intended final flavour.

In making fruit rakia, the distillers aim to preserve the initial flavour. By blending two different aromas, they will venture into cocktails instead of having a clean and easily identifiable product.

They can not blend spirits with different maturity, as aging changes the rakia’s expected aroma and colour.

Blending is more straightforward to implement in grape rakia but depends on the grape used. The less aromatic types are the most suitable for that purpose, similar to cognac, as they benefit the most from the maturation aroma impact.

Spirits Bottling and Marketing

By bottling, I don’t mean when the spirit is bottled, but why is it important to do it? As trivial as it may sound, the packaging decision usually makes or breaks a product on the commercial market, especially internationally.

The spirits market is highly competitive. Every producing company aims to create a niche, enter a new market, differentiate from other competitors, and maximize the profit potential of its products.

Having a good product is half the work; the more difficult part is convincing people to buy your drinks instead of someone else’s.

Why consumers buy what they buy

Consumers base their decisions on internal and external searches. About 70% of potential buyers in the store are unsure what they will buy. Their decisions are based on subconscious, irrational feelings about how an item looks, how it makes them feel, what memories bring back to life, remembering other people’s reviews, etc.

We can generally summarize the consumers’ approach to decision-making as follows:

- Internal search is based on their experience; most people will go for something familiar if they are not convinced by the product design or lack knowledge. It creates a steeper obstacle for new entrants to a market.

- An external search is about acting upon other consumers’ feedback for a particular product on social platforms, reviews, and search engine results.

Once the producers understand why people might buy similar products and their psychological motives, they can design a marketing strategy to explore new opportunities and maximize their sales successfully.

Emotional Factors

Targeting an irrational cause for making a decision can be done by looking at the triggers.

- Packaging – Rakia producers are already doing an excellent job at bottle design. I would say it is better than vodka, gin, or whisky; where they are lacking is more exposure. Packaging represents instant communication in a way:

- Buyers are aware of it

- It is present at the crucial moment when the decision to buy is made

- Buyers are actively involved with packaging as they examine it to obtain the necessary information.

- market appeal

- cost

- innovation

- creating consumer loyalty

- brand equity – being compared to a well-known similar spirit brand

- Colour is considered part of the packaging but also deserves a closer look.

It is probably the most important and influential element in a person’s decisions and evaluations. Colour profoundly affects consumers’ behaviour, thoughts, and subconscious – the main trigger of our shopping intentions.

Different colours influence human psychology differently, and the way we perceive colour is based on our cultural upbringing, income, gender, personality, etc. The focus should be on researching the colour perceptions and associations of the target market.

Colour examples of perceptions

| white | youth, light, truth, cleanliness |

| yellow | joy, sunlight, sociability, wealth, friendship |

| red | celebration, energy, excitement, masculinity, purity |

| blue | royalty, wisdom, creativity |

| green | good luck, inteligence |

| orange | energy, desire, heat |

The meaning of colour in the West might be associated with other potentially negative perceptions in Asia or other parts of the world.

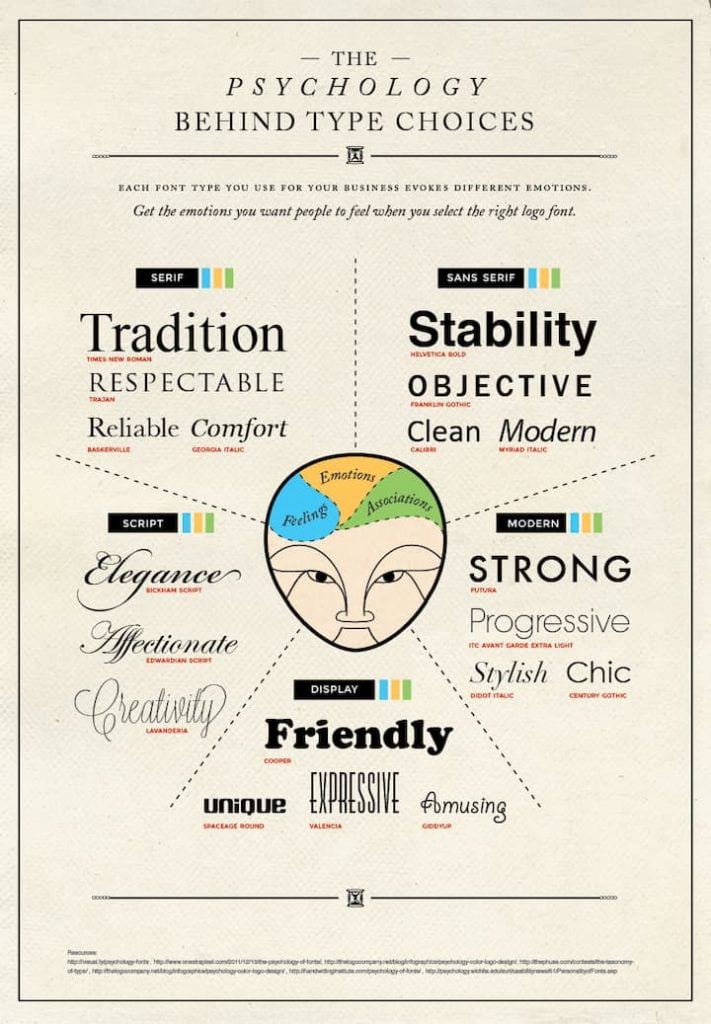

- Font – The text on the product is essential for effective communication. It may help attract consumers or convey a perception of exclusivity. Some examples of fonts used in marketing are:

- Serif is used in formal marketing, which implies expensive and warm.

- Uchronia – desire

- Sans-Serif – less formal communication. It implies youth, modernity, and coolness.

- Freight Sans medium- Script fonts – handwritten, expensive, soft, delicate, relaxed, happy.

Designing packaging/bottling is not a process that should be taken lightly. It is a science that is becoming more critical, especially given consumers’ increased screen time, the abundance of social platforms, and easy access to information.

Well-designed packaging means a functional and pleasing experience seamlessly integrated into everyday life for the consumer. Consumer-oriented packaging can benefit a business by creating a competitive advantage, increasing customer satisfaction, and boosting sales.

And one last thing about advertising.

Don’t just use comparative marketing (mine is better than yours); focus on how people will feel if they buy your product.

I’m finishing this article as I started it, talking about marketing. The “Rakia Belt” needs to realize that having such a great product, with so much variety and traditions, should not be left to individual producers to market the spirit or to the EU to tell them how to classify one of the world’s oldest drinks. Still, all these countries (producers, resellers, governments) should establish a common strategy for proper marketing to put the rakia on the world stage.

EU Recognition of Geographical Indication

Geographical indications are distinctive signs that differentiate competing goods and collectively important assets in designing a marketing strategy.

According to the European Commission:

A geographical indication shall be an indication which identifies a spirit drink as originating in the territory of a country, or a region or locality in that territory, where a given quality, reputation or other characteristic of that spirit drink is essentially attributable to its geographical origin.

https://eur-lex.europa.eu/legal-content

This is a small sample of some European countries’ GI-designated spirits. For a complete listing, check this post on Geographical Indication.

12 Records – Bulgaria Geographical Indication (GI) of Rakia

| Spirit drink | Bulgaria | Geographical indication (GI) | PGI-BG-01864 | Grozdova rakya ot Targovishte | 4. Wine spirit | Registered | 28/11/2018 | |

| Spirit drink | Bulgaria | Geographical indication (GI) | PGI-BG-01865 | Karnobatska grozdova rakya / Grozdova rakya ot Karnobat | 4. Wine spirit | Registered | 30/11/2018 | |

| Spirit drink | Bulgaria | Geographical indication (GI) | PGI-BG-01867 | Yambolska grozdova rakya / Grozdova rakya ot Yambol | 4. Wine spirit | Registered | 09/10/2019 | |

| Spirit drink | Bulgaria | Geographical indication (GI) | PGI-BG-01862 | Troyanska slivova rakya / Slivova rakya from Troyan | 9. Fruit spirit | Registered | 21/06/2005 | |

| Spirit drink | Bulgaria | Geographical indication (GI) | PGI-BG-01863 | Loveshka slivova rakya / Slivova rakya from Lovech | 9. Fruit spirit | Registered | 21/06/2005 | |

| Spirit drink | Bulgaria | Geographical indication (GI) | PGI-BG-01860 | Suhindolska grozdova rakya / Grozdova rakya from Suhindol | 4. Wine spirit | Registered | 21/06/2005 | |

| Spirit drink | Bulgaria | Geographical indication (GI) | PGI-BG-01855 | Sungurlarska grozdova rakya / Grozdova rakya from Sungurlare | 4. Wine spirit | Registered | 21/06/2005 | |

| Spirit drink | Bulgaria | Geographical indication (GI) | PGI-BG-01857 | Straldjanska Muscatova rakya / Muscatova rakya from Straldja | 4. Wine spirit | Registered | 21/06/2005 | |

| Spirit drink | Bulgaria | Geographical indication (GI) | PGI-BG-01856 | (Slivenska grozdova rakya / Grozdova rakya from Sliven) | 4. Wine spirit | Registered | 21/06/2005 | |

| Spirit drink | Bulgaria | Geographical indication (GI) | PGI-BG-01858 | Pomoriyska grozdova rakya / Grozdova rakya from Pomorie | 4. Wine spirit | Registered | 21/06/2005 | |

| Spirit drink | Bulgaria | Geographical indication (GI) | PGI-BG-01861 | Rakya from Karlovo | 4. Wine spirit | Registered | 21/06/2005 | |

| Spirit drink | Bulgaria | Geographical indication (GI) | PGI-BG-01859 | Bourgaska Muscatova rakya / Muscatova rakya from Bourgas | 4. Wine spirit | Registered | 21/06 |

1 Records – Cyprus GI

| Spirit drink | Cyprus | Geographical indication (GI) | PGI-CY-01942 | Ζιβανία / Τζιβανία / Ζιβάνα / Zivania | 6. Grape marc spirit or grape marc | Registered | 13/02/2008 |

5 Records – Greece – GI – Grape marc

| Spirit drink | Greece | Geographical indication (GI) | PGI-GR-02079 | Τσίπουρo / Tsipouro | 6. Grape marc spirit or grape marc | Registered | 13/02/2008 | |

| Spirit drink | Greece | Geographical indication (GI) | PGI-GR-02038 | Tsipouro of Macedonia | 6. Grape marc spirit or grape marc | Registered | 12/06/1989 | |

| Spirit drink | Greece | Geographical indication (GI) | PGI-GR-02019 | Tsipouro of Tyrnavos | 6. Grape marc spirit or grape marc | Registered | 12/06/1989 | |

| Spirit drink | Greece | Geographical indication (GI) | PGI-GR-02022 | Tsipouro of Thessaly | 6. Grape marc spirit or grape marc | Registered | 12/06/1989 | |

| Spirit drink | Greece | Geographical indication (GI) | PGI-GR-02054 | Tsikoudia of Crete | 6. Grape marc spirit or grape marc | Registered | 12/06/1989 |

15 Records Hungary GI

| Spirit drink | Hungary | Geographical indication (GI) | PGI-HU-02489 | Madarasi birspálinka | 9. Fruit spirit | Published | 31/05/2021 | |

| Spirit drink | Hungary | Geographical indication (GI) | PGI-HU-02232 | Nagykunsági szilvapálinka | 9. Fruit spirit | Registered | 03/05/2021 | |

| Spirit drink | Hungary | Geographical indication (GI) | PGI-HU-02408 | Vasi vadkörte pálinka | 9. Fruit spirit | Registered | 25/03/2021 | |

| Spirit drink | Hungary | Geographical indication (GI) | PGI-HU-02490 | Sárréti kökénypálinka | 9. Fruit spirit | Applied | 06/03/2019 | |

| Spirit drink | Hungary | Geographical indication (GI) | PGI-HU-02477 | Nagykörűi cseresznyepálinka | 9. Fruit spirit | Applied | 13/07/2018 | |

| Spirit drink | Hungary | Geographical indication (GI) | PGI-HU-02471 | Homokháti őszibarack pálinka | 9. Fruit spirit | Applied | 25/05/2018 | |

| Spirit drink | Hungary | Geographical indication (GI) | PGI-HU-02233 | Nagykunsági birspálinka | 9. Fruit spirit | Applied | 18/10/2016 | |

| Spirit drink | Hungary | Geographical indication (GI) | PGI-HU-01829 | Újfehértói meggypálinka | 9. Fruit spirit | Registered | 04/02/2014 | |

| Spirit drink | Hungary, Austria | Geographical indication (GI) | PGI-HU+AT-02048 | Pálinka | 9. Fruit spirit | Registered | 13/02/2008 | |

| Spirit drink | Hungary | Geographical indication (GI) | PGI-HU-02052 | Gönci Barackpálinka | 9. Fruit spirit | Registered | 13/02/2008 | |

| Spirit drink | Hungary | Geographical indication (GI) | PGI-HU-02031 | Törkölypálinka | 9. Fruit spirit | Registered | 13/02/2008 | |

| Spirit drink | Hungary | Geographical indication (GI) | PGI-HU-02039 | Szabolcsi Almapálinka | 6. Grape marc spirit or grape marc | Registered | 23/09/2003 | |

| Spirit drink | Hungary | Geographical indication (GI) | PGI-HU-02042 | Kecskeméti Barackpálinka | 9. Fruit spirit | Registered | 23/09/2003 | |

| Spirit drink | Hungary | Geographical indication (GI) | PGI-HU-02053 | Békési Szilvapálinka | 9. Fruit spirit | Registered | 23/09/2003 | |

| Spirit drink | Hungary | Geographical indication (GI) | PGI-HU-02047 | Szatmári Szilvapálinka | 9. Fruit spirit | Registered | 23/09/2003 |

1 Record – Spain -GI- Grape marc

| Spirit drink | Spain | Geographical indication (GI) | PGI-ES-01914 | Orujo de Galicia | 6. Grape marc spirit or grape marc | Registered | 12/06/1989 |

9 Records – Romania GI

| Spirit drink | Romania | Geographical indication (GI) | PGI-RO-02005 | Pălincă | 9. Fruit spirit | Registered | 13/02/2008 | |

| Spirit drink | Romania | Geographical indication (GI) | PGI-RO-02012 | Vinars Vaslui | 9. Fruit spirit | Registered | 21/06/2005 | |

| Spirit drink | Romania | Geographical indication (GI) | PGI-RO-02000 | Vinars Murfatlar | 4. Wine spirit | Registered | 21/06/2005 | |

| Spirit drink | Romania | Geographical indication (GI) | PGI-RO-02001 | Țuică Zetea de Medieșu Aurit | 4. Wine spirit | Registered | 21/06/2005 | |

| Spirit drink | Romania | Geographical indication (GI) | PGI-RO-02011 | Vinars Vrancea | 9. Fruit spirit | Registered | 21/06/2005 | |

| Spirit drink | Romania | Geographical indication (GI) | PGI-RO-02007 | Vinars Târnave | 4. Wine spirit | Registered | 21/06/2005 | |

| Spirit drink | Romania | Geographical indication (GI) | PGI-RO-02004 | Horincă de Cămârzana | 4. Wine spirit | Registered | 21/06/2005 | |

| Spirit drink | Romania | Geographical indication (GI) | PGI-RO-02006 | Vinars Segarcea | 9. Fruit spirit | Registered | 21/06/2005 | |

| Spirit drink | Romania | Geographical indication (GI) | PGI-RO-02003 | Țuică de Argeș | 4. Wine spirit | Registered | 21/06/20 |

2 Records – Slovenia GI

| Spirit drink | Slovenia | Geographical indication (GI) | PGI-SI-01826 | Dolenjski sadjevec | 9. Fruit spirit | Registered | 13/02/2008 | |

| Spirit drink | Slovenia | Geographical indication (GI) | PGI-SI-01830 | Brinjevec | 9. Fruit spirit | Registered | 13/02/2008 |

Footnotes

- https://rakiashop.eu/rakia-vs-whiskey-co/

- Radio Bulgaria

- gotvarstvo

- rozbul

- Hieronymus_Brunschwig

- How to make homemade rakia – Prof. D. Tzakov’s secrets. Book, 2011

- Spaho, Nermina. (2017). Distillation Techniques in the Fruit Spirits Production. 10.5772/66774.

- bgfermer

- http://www.thegoodscentscompany.com/odor/alcoholic.html#seventh

- rakiashop.bg

- Vesna Kostik, Shaban Memeti – Institute of Public Health, North Macedonia, 2013

Biljana Bauer – Institute of Pharmacognosy, Faculty of Pharmacy, Ss. Cyril and Methodius University - Nermina Spaho

- https://pdfs.semanticscholar.org/77fc/3b281b76388d2c137307ac1155a7987f173f.pdf

Very nice post. I just stumbled upon your weblog and wanted to say that I have really enjoyed browsing your weblog posts.

In any case I will be subscribing on your feed and I hope you write again soon!

Thank you. I appreciate it.

I like the helpful info you provide in your articles. I’ll bookmark your blog and check again here frequently.

I’m quite sure I will learn plenty of new stuff

right here! Best of luck for the next!

Thanks in support of sharing such a nice thinking, post is nice, thats why

i have read it completely

Thank you.

Hi, after reading this remarkable paragraph i am as

well happy to share my familiarity here with colleagues.

Thank you.

I love what you guys are up too. This type of

clever work and reporting! Keep up the awesome works guys I’ve

you guys to our blogroll.

Hello to every single one, it’s truly a nice for me

to visit this web page, it contains precious Information.

First of all I would like to say superb blog! I had a quick

question which I’d like to ask if you do not mind.

I was interested to find out how you center yourself and clear your head before writing.

I have had trouble clearing my mind in getting my thoughts out.

I truly do take pleasure in writing but it just seems like

the first 10 to 15 minutes are usually lost just trying to figure out how to begin. Any suggestions or tips?

Kudos!

Thank you for your comment. I start writing about whatever comes to my mind. Later I go back and edit it.

If some one wishes expert view regarding running a blog afterward

i propose him/her to go to see this website, Keep up the nice work.

I am regular reader, how are you everybody? This article posted at this web site is really good.

Pretty! This has been an extremely wonderful post.

Thank you for supplying this info.

Thank you.

Somebody essentially assist to make critically posts

I would state. This is the first time I frequented your web page and to this point?

I amazed with the analysis you made to create this actual

put up amazing. Great process!

Thank you.

Great article. I’m going through some of these

issues as well..

Entraîner les muscles website musculation

Great blog here! Also your site loads up fast! What web host

are you using? Can I get your affiliate link to your host?

I wish my site loaded up as quickly as yours lol

Thank you.

My host is HawkHost. You can use this link to sign up.

https://my.hawkhost.com/aff.php?aff=16334

It has been simply incredibly generous with you to provide openly what exactly many individuals

would’ve marketed for an ebook to end up making some cash for their end, primarily given that you could have tried it in the

event you wanted.

Hello there! This is my first comment here, so I just wanted to give a quick

shout out and say I genuinely enjoy reading your articles.

Can you recommend any other blogs/websites/forums that deal with

the same subjects? Thanks.

Thank you. I don’t have direct links to similar sites, try Difford’s guide, it has a lot of recipes.

I enjoy what you guys are usually up too. This sort of clever work and

coverage! Keep up the wonderful works guys I’ve added you guys to my blogroll.

It’s remarkable to visit this site and reading the views of all colleagues on the topic of this

article, while I am also eager of getting familiarity.

Thank you.

Good site you have here.. It’s hard to find good quality writing like

yours these days. I really appreciate individuals like you!

Take care!!

Pump muscle website how

to pummp the press

Thank you.

I read this post completely concerning the comparison off latest and previous technologies, it’s awesome article.

Farmacología deportiva webpage entrenamiento muscular

Thank you.

And indeed, I’m just always astounded concerning the remarkable things served by you.

Some four facts on this page are undeniably the most effective I’ve had.

Thanks for sharing your info. I truly appreciate your efforts and I am waiting for your next write ups thank you once again.

Thank you.

Good blog you have got here.. It’s hard to find excellent writing like yours

these days. I truly appreciate people like you! Take care!!

Wow, amazing blog layout! Hoow long have you been blogging for?

you make blogging look easy. The overall look of your web site is wonderful,

let alone the content!

Stéroïdes anabolisants juridiques homepage Entraîner les muscles

I’m really enjoying the design and layout of your blog.

It’s a very easy on the eyes which makes it much more enjoyable

for me to come here and visit more often. Did you hire out a developer to create your theme?

Great work!

Feel free to visit my homepage :: tracfone special

Thank you for your kind comments.

Hi! Do you know if they make any pluggins to assist

with Search Engine Optimization? I’m trying to get mmy

blog tto rank for some targeted keywords but I’m not seeing vry good success.

If you know oof any please share. Kudos!

Pompe musculaire pour homme webpage médecine sportive

If you are using WordPress, search for SEO plugins. I ve heard good things about Rankmath

Hmm it appears like your site ate my first comment (it

was extremely long) so I guess I’ll just sum it up what

I had written and say, I’m thoroughly enjoying your blog.

I too am an aspiring blog writer but I’m still new to everything.

Do you have any recommendations for newbie blog writers?

I’d certainly appreciate it.

Thank You for your comment, pick a topic you personally like and stick to the point. Easy said than done, but enjoy what are you written about.

This is the perfect webpage for anyone who really wants to find out about

this topic. You realize so much its almost hard to argue with you (not that I

really would want to…HaHa). You definitely put a brand new spin on a subject that

has been written about for years. Wonderful stuff, just

wonderful!

Thank you.

Magnificent beat ! I would like to apprentice while you amend your site,

how could i subscribe for a blog web site? The account aided me a acceptable deal.

I had been a little bit acquainted of this your broadcast offered bright clear idea